JBX/JNX

JBX/JNX

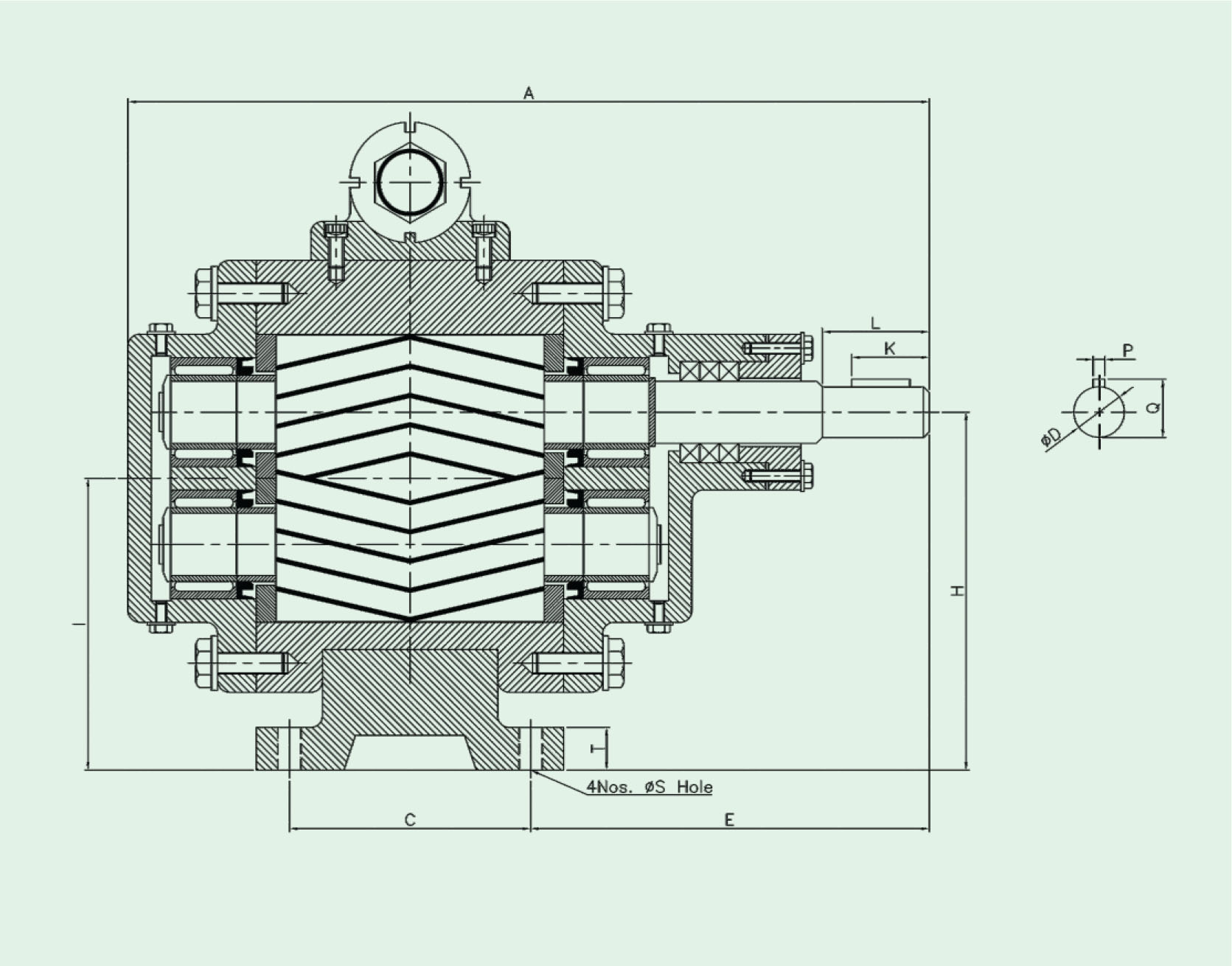

This series contains special purpose foot and flange mounted pumps with flange end at inlet & outlet ports.

MATERIAL OF CONSTRUCTION STANDARD

| Pump Body | Graded CI Casting |

|---|---|

| Gears | Alloy Steel - double Helical - H. Nitrided |

| Shaft | Alloy Steel - Case Hardened & ground |

| Bearings & Bushes | Needle Roller bearing (JNX) / Bronze Bushes (JBX) |

| Sealing | Oil Seal/Teflon base 'Z'pack |

| Size | ½" to 6" (10 different sizes) |

| Range | 0.50 to 2080 LPM |

| Liquid | Crude oil, dirty oil, kerosene, LDO, HSD, Wood Pulp,Furnace oil etc. |

| Viscosity | up to 1,00,000 |

| Tempreture | up to 200 °C |

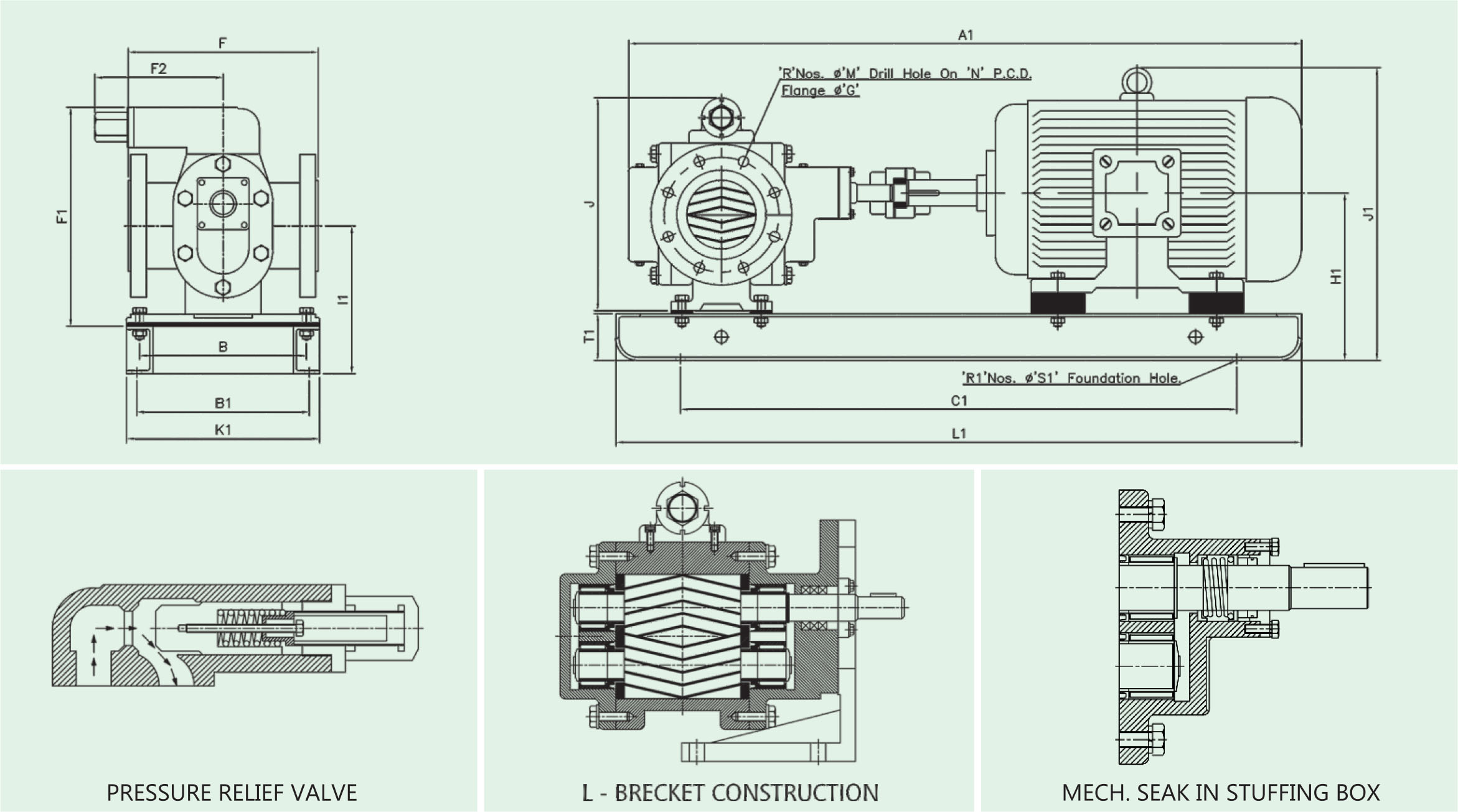

| In Built Pressure Relief valve is provided to acheive maximum working prssure-21kg/cm2 | |

Shivam Enterprise we are involved in manufacturing, quality control, selling, installing and servicing of Rotary Gear Pumps.

Shivam Enterprise offer gear pump Model "JBX/JNX" which is heavy duty flange and foot mounting type positive displacement rotary gear pump. Model "JBX/JNX" is modified version of Model "JBX/JNX" to achieve high pressure. These pumps having doubled helical finished gears and hardened & ground shafts. Due to double helical gear it prevent axial load and side thrust which help to increase life and performance of pump.

In these pumps size 1/2" to 2 1/2" are provided with thread at end of suction & delivery and they are available with foot or flange mounting, But in size 3" to 4" are provided with flange at the end of suction & delivery and they are available with foot mounting only. These pumps flange are as per standard AFA/ANSI - 300 class. These pumps can be operated up to pressure of 20 kg/cm2 with 5.0 LPM to 900 LPM flow capacity. These pumps are suitable for liquid up to viscosity of 1, 00,000 SSU and maximum temperature up to 2000C.

APPLICATION

- Power plant.

- Steel plant.

- Cement plant.

- Bitumen plant.

- Petroleum industries. Refineries.

- Pumping station.

- All kind of liquid loading and unloading.

FEATURES

- High pressure pump offered to 20 Bar.

- Heavy duty gear pump design for continuous application.

- Modification tooth profile enhances the tool life.

- Floating gear design ensures uniform load distribution.

- Heavy duty gear pump double helical design prevent axial load and side thrust.

- Shorter bearing span reduces bending effect.

- Low leakage path by design improve volumetric efficiency.

| Material of construction | ||

|---|---|---|

| Model | Material for JNX | Material for JBX |

| Pump Body | CI/CS/SS | CI/CS/SS |

| Front Cover | CI/CS/SS | CI/CS/SS |

| Back Cover | CI/CS/SS | CI/CS/SS |

| Gland Cover | CI/CS/SS | CI/CS/SS |

| Rotor / Stator Shaft | EN-19/SS | EN-19/SS |

| Gear | EN-24/SS | EN-24/SS |

| Needle / Bush Bearing | INA/IKO [Japan] | Non - Ferrous |

| Wear Plate | Bronze | Bronze |

| Sealing | "GFO" Pack Teflon/Mech. Seal | "GFO" Pack Teflon/Mech. Seal |

| R.V. Housing | Mild Steel/SS | Mild Steel/SS |

| R.V. Piston | EN-8/SS | EN-8/SS |

| R.V. Spring | Spring Steel | Spring Steel |

| R.V. AD. Screw | EN-8 | EN-8 |

| Кеу | EN-8 | EN-8 |

| Hex - Bolt | Mild Steel/SS | Mild Steel/SS |

Available Size & Capacity

| Size & Model | 1440 RPM Capacity | Pump GD 2 in KGM2 | Ele Motor HP | Fr. Size | |||

|---|---|---|---|---|---|---|---|

| LPM | US GPM | M3/hr | |||||

| 1/2" 050 |

S M L |

05.00 08.33 16.66 |

01.32 02.21 04.42 |

0.30 0.50 1.00 |

0.0001 0.0002 0.0003 |

0.50 1.00 1.50 |

71 M 80 M 90 S |

| 1" 100 |

S M L |

25.00 33.32 41.65 |

06.60 08.80 11.00 |

1.50 2.00 2.50 |

0.0005 0.0006 0.0008 |

1.00 2.00 3.00 |

80 M 90 L 100 L |

| 1.1/4 125 |

S M L |

50.00 60.00 83.00 |

13.25 16.66 22.00 |

3.00 3.60 5.00 |

0.0005 0.0006 0.0008 |

2.00 3.00 5.00 |

90 L 100 L 112 M |

| 1.1/2 150 |

S M L |

100.00 125.00 150.00 |

26.50 33.00 39.75 |

6.00 7.50 9.00 |

0.0045 0.0057 0.0068 |

3.00 5.00 7.50 |

100 L 112 M 132 S |

| 2" 200 |

S M L |

166.60 200.00 250.00 |

44.16 53.00 66.25 |

10.00 12.00 15.00 |

00.0068 00.0081 00.0100 |

5.00 10.00 15.00 |

112 M 132 M 160 M |

| 2.1/2" 250 |

S M L |

300.00 333.00 350.00 |

79.50 88.33 92.75 |

18.00 20.00 21.00 |

0.0160 0.0174 0.0185 |

7.50 15.00 20.00 |

132 S 160 L 160 L |

| 3" 300 |

S M L |

400.00 450.00 600.00 |

106.00 119.00 159.00 |

27.00 27.00 36.00 |

0.0361 0.0469 0.0560 |

25.00 30.00 35.00 |

180 M 180 L 200 L |

| 4" 400 |

S M L |

700.00 800.00 900.00 |

185.50 212.00 238.50 |

42.00 48.00 54.00 |

0.0750 0.0870 0.0980 |

40.00 50.00 60.00 |

200 L 225 S 225 M |

| 5" 500 |

S M L |

1000.00 1200.00 1400.00 |

265.00 318.00 371.00 |

60.00 72.00 84.00 |

0.1680 0.2800 0.2410 |

60.00 75.00 100.00 |

225 M 280 S 250 M |

| 6" 600 |

S M L |

1666.00 1915.00 2082.00 |

441.50 508.00 552.00 |

100.00 115.00 125.00 |

0.3245 0.3683 03947 |

75.00 100.00 120.00 |

250 M 280 S 280 M |

| Dimensions | Weight | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall | Mounting | Shaft | Flange | ||||||||||||||||||

| A1 | J A |

J1 | L1 | K1 | F1 | F2 | B C |

S S1 |

E F |

H I |

H1 | T T1 |

C1 | B1 | I1 | D R1 |

K L |

P Q |

M N |

G R |

BP-COU PUMP IN KG. |

| 455 505 522 |

139 --- 206 |

235 251 225 |

425 450 475 |

140 150 180 |

143 153 162 |

- 112 - |

119 - 40 |

8.5 - 15 |

58 - 100 |

71 - 60 |

115 124 134 |

15 - 40 |

370 405 430 |

112 112 140 |

104 113 123 |

11.5 - 04 |

22 - 25 |

04 - 13 |

M8 - 66.6 |

Sq65 - 04 |

7.00 6.00 7.50 |

| 520 560 599 |

151 --- 219 |

251 225 279 |

500 525 550 |

170 180 200 |

155 165 174 |

- 112 - |

125 - 45 |

8.5 - 15 |

69 - 120 |

80 - 64 |

124 134 144 |

15 - 40 |

445 480 505 |

135 1140 160 |

108 118 128 |

15 - 04 |

25 - 30 |

05 - 17 |

M8 - 73 |

Sq70 - 04 |

10.15 11.00 13.00 |

| 591 630 658 |

185 --- 250 |

235 289 323 |

550 600 600 |

180 200 230 |

189 195 211 |

- 141 - |

155 - 50 |

10 - 15 |

81 - 135 |

90 - 70 |

144 154 166 |

15 - 50 |

485 545 545 |

140 160 190 |

124 134 146 |

21 - 04 |

30 - 40 |

06 - 23.5 |

M10 - 85 |

Sq80 - 04 |

12.00 14.50 15.50 |

| 673 700 764 |

205 --- 293 |

289 321 362 |

625 650 700 |

200 230 250 |

207 220 241 |

- 153 - |

170 - 55 |

12 - 15 |

95 - 145 |

100 - 78 |

154 166 186 |

20 - 50 |

570 595 645 |

160 190 216 |

132 144 164 |

24 - 04 |

40 - 50 |

08 - 27 |

M12 - 106 |

Sq100 - 04 |

15.00 24.00 18.75 |

| 746 850 950 |

234 --- 339 |

338 377 435 |

700 825 900 |

230 250 285 |

238 258 286 |

- 173 - |

200 - 70 |

12 - 19 |

94 - 165 |

112 - 86 |

181 205 229 |

20 - 65 |

630 755 830 |

190 216 230 |

155 175 203 |

27 - 04 |

40 - 55 |

08 - 30 |

M12 - 127 |

Sq120 - 04 |

18.00 35.00 21.00 |

| 850 990 1030 |

261 --- 375 |

387 445 445 |

800 900 950 |

260 315 315 |

266 294 294 |

- 173 - |

225 - 80 |

15 - 19 |

104 - 190 |

132 - 103 |

211 239 239 |

25 - 75 |

550 650 700 |

200 254 254 |

182 210 210 |

32 - 04 |

50 - 60 |

10 - 35 |

M14 - 149 |

Sq135 - 04 |

19.00 55.00 23.00 |

| 1165 1165 1235 |

338 --- 436 |

568 568 616 |

1150 1150 1200 |

330 330 355 |

342 342 362 |

- 205 - |

180 - 90 |

19 - 19 |

244 - 280 |

180 - 146 |

284 284 304 |

25 - 100 |

850 850 900 |

279 279 318 |

250 250 270 |

37 - 04 |

55 - 65 |

10 - 40 |

22 - 168 |

210 - 08 |

33.00 73.00 37.00 |

| 1285 1330 1360 |

375 --- 487 |

616 666 666 |

1300 1400 1400 |

370 406 406 |

379 404 404 |

- 230 - |

180 - 130 |

19 - 22 |

258 - 300 |

200 - 160 |

304 329 329 |

28 - 100 |

900 900 900 |

318 356 356 |

264 289 289 |

47 - 04 |

70 - 80 |

14 - 50.5 |

22 - 200 |

254 - 08 |

52.00 92.00 58.00 |

| 1405 1495 1590 |

420 --- 533 |

691 794 854 |

1450 1550 1600 |

430 470 520 |

424 449 479 |

- 230 - |

200 - 150 |

22 - 22 |

271 - 340 |

225 - 179 |

354 379 409 |

28 - 150 |

1050 1050 1150 |

256 406 457 |

308 333 363 |

52 - 04 |

75 - 85 |

16 - 56 |

22 - 235 |

279 - 08 |

52.00 142.00 76.00 |

| 1510 1610 1610 |

467 --- 550 |

819 879 879 |

1650 1700 1700 |

470 520 520 |

471 501 501 |

- 245 - |

215 - 170 |

22 - 22 |

293 - 345 |

250 - 200 |

404 434 434 |

28 - 150 |

1150 1150 1150 |

406 457 457 |

354 384 384 |

57 - 04 |

80 - 95 |

16 - 61 |

22 - 270 |

317 - 12 |

78.00 173.00 85.00 |

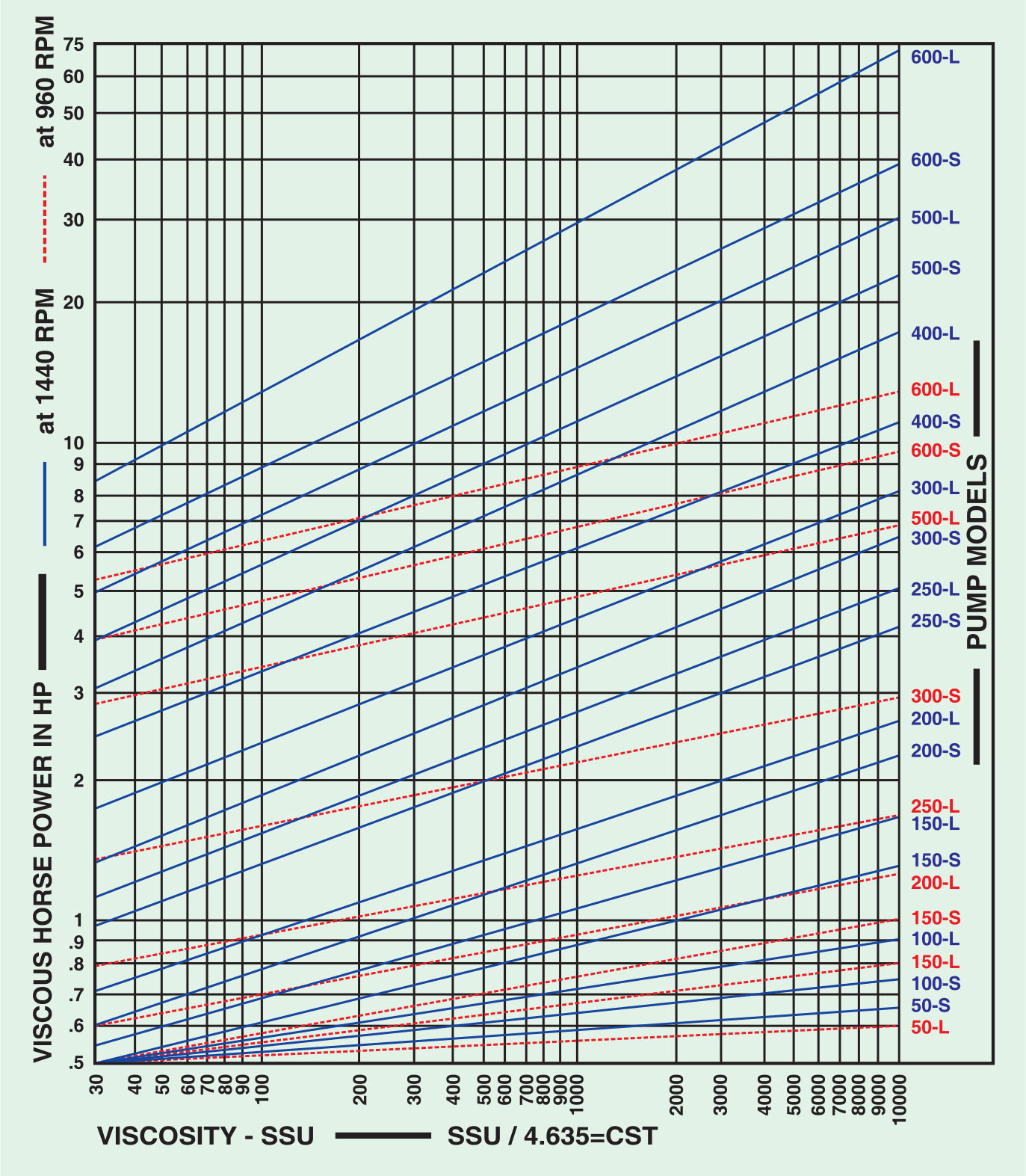

PUMP CHARACTERISTIC

Gear Pump is versatile rotary positive displacement pump with positive Pressure characteristic. The capacity of the pump is directly proportional to the speed but remain constant against pressure the different between theoretical and delivery capacity is the slip of the pump which depends on speed, Viscosity of liquid working clearance, Differential pressure & workman Ship. The pumps are capable of handling any kind of viscosity, the slip reduce with viscosity but the viscous power increase due to the resistance of the fluid to shear. The pump has a self priming capability however some net inlet pressure available must always equal or positive suction head NPSH is always required to avoid cavitations depending upon the viscosity of the liquid to be pumped & the pump speed

PUMP HORSEPOWER AND EFFICIENCY

The brake horsepower required to drive a rotary gear pump is the sum of the theoretical horsepower and the internal power losses. The theoretical liquid horsepower is the actual work done in moving the liquid from the inlet pressure condition to the outlet at discharge pressure. This work is done well on all the fluid of theoretical capacity, not just delivered capacity, as slip does not exist until a pressure differential offer. Note that, theoretical liquid horsepower is independent of viscosity and is concerned only with the physical dimension of the pumping elements, the rotating speed and the differential pressure.

THE INTERNAL POWER LOSSES

The Internal Power Losses are made up of two types: mechanical and viscous. The mechanical losses include all power necessary to overcome the mechanical friction drag of all the moving parts within the pump, including bearings, gears, mechanical seal etc. The viscous losses include all the power lost from the fluid viscous drag effects against all the parts within the pump as well as from the shearing action of the fluid itself.

It is probable that the mechanical loss is the major component when operating at low viscosities and high speeds while the viscous loss is the larger at high viscosity and slow speed conditions.

PUMP SPEED

Model "JBX/JNX" are recommended to run at rated speed up to 500 CST viscosity, For viscosity between 500 to 1250 CST pump speed should be reduce up to 60% of rated speed, For Viscosity between 1250 to 2500 CST speed should be reduce up to 30% of rated speed.

PUMP SELECTION

The self lubricated needle roller bearing type Model JNX used in clean liquid having sufficient lubricating property such as clean lube oil, Gear oil, Animal oil, Fish oil, Hydraulic oil, Vegetable oil. However self lubricated bush bearing type model JBX used in viscous liquids and semi viscous liquids. Model "JBX" is a bush bearing type pump which can be used for viscous liquid having sufficient lubricating value for intermittent duty; however for continuous duty, pump have needle roller bearing in Model "JNX" and it will be selected for liquid having low viscosity, power lubricating values.