JRG/SS

JRG/SS

For Handling Of Corrosive, Hygienic, Abbrasive Viscous Liquid To Transfer, Loading-Unloading & Pressuring Applicaion.

Under "JIKSAN" brand name JRG-SS series external gear pumps are self priming bi-directional, positive displacement rotary pump in all stainless steel (SS-316) construction with dry lubrication PTFE coated DU bush bearing. These pumps are easy cleanable, easy maintainable in 3-piece construction. The back cover can simply be removed 4-dom nut. The right angle mounting brackets facilitates foot mounting of the pump on base plate with electric motor of appropriate ratings.

MATERIAL OF CONSTURUCTION

| Pump Body | CF8M (S.S.316) |

|---|---|

| Front Cover | CF8M (S.S.316) |

| Back Cover | CF8M (S.S.316) |

| Seal Cover | CF8M (S.S.316) |

| Gears | AISI S.S.316 |

| Shaft | AISI S.S.316 |

| Bush Bearing | PTFE coated 'DU' |

| Mounting Bracket | C.I. Gr.-20 IS 210 |

| Dom Nut/ Ln Bolt | AISI S.S. 316 |

| Sealing | "Z" Pack Teflon |

| Packing | Teflon Sheet |

| Key For Coupling | AISI S.S. 316 |

| Pump Model JRG-SS | Suction & Delivery (Screw End) | Capacity at 1440 RPM | Power req. | Pump Dimensions |

Wt. of pump in kg. aprox |

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LPM | US GPM | M3/hr | No Load Viscous HP. At |

Unit HP. Per Kg. Press |

Over all | Mounting & Shaft |

||||||||||||||||

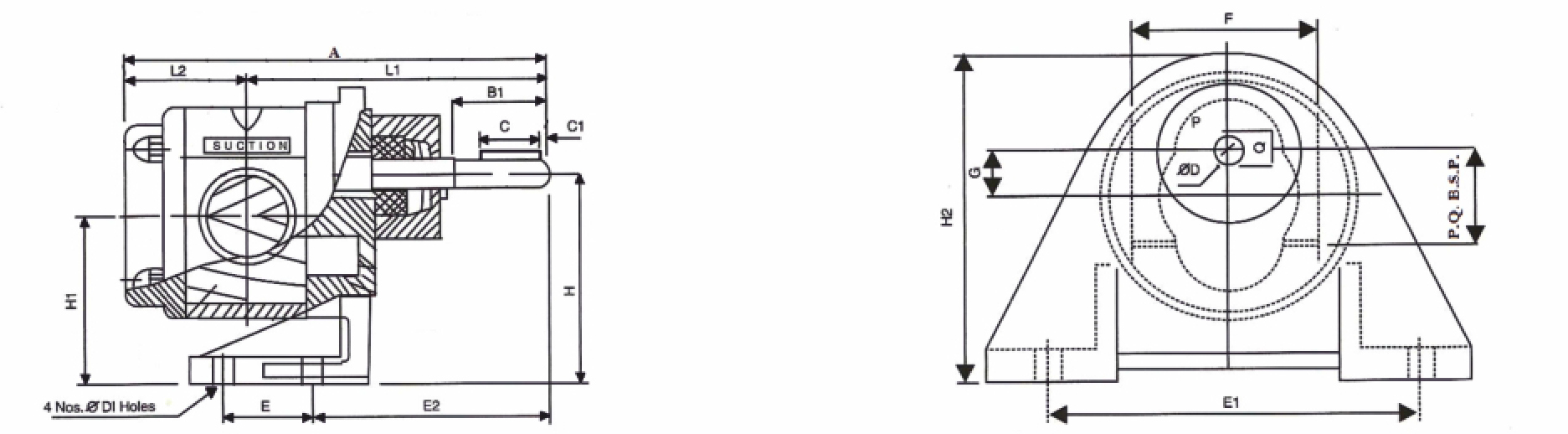

| 200 CSt | 200 CSt | A | FG | H2 | L1 | L2 | E | E1 | E2 | H | H1 | D D1 | C C1 | PQ | B1 | |||||||

| 25 | 1/4" x 1/4" | 54 | 11.5 | 17 | 4 | |||||||||||||||||

| 8.33 | 2.2 | 0.50 | 0.20 | 0.25 | 0.02 | 129 | 12.5 | 101 | 94 | 35 | 40 | 120 | 82 | 63 | 50.5 | 8 | 3 | 13 | 25 | 2.50 | ||

| 40 | 3/8" x 3/8" | 16.66 | 4.4 | 1.00 | 0.35 | 0.40 | 0.04 | 134 | 61 | 112 | 98 | 36 | 50 | 120 | 88 | 71 | 57 | 11.5 | 17 | 4 | 25 | 3.50 |

| 50 | 1/2" x 1/2" | 25.00 | 6.6 | 1.50 | 0.40 | 0.50 | 0.06 | 146 | 14 | 112 | 103 | 41 | 50 | 120 | 88 | 71 | 57 | 8 | 3 | 13 | 25 | 4.50 |

| 75 | 3/4" x 3/4" | 33.33 | 8.8 | 2.00 | 0.45 | 0.55 | 0.085 | 160 | 72.5 | 128 | 123 | 46 | 55 | 140 | 92 | 90 | 73 | 14 | 25 | 5 | 35 | 6.50 |

| 100 | 1" x 1" | 50.00 | 13.2 | 3.00 | 0.50 | 0.60 | 0.13 | 177 | 17 | 128 | 115 | 52 | 55 | 140 | 92 | 90 | 73 | 10.5 | 3 | 16 | 35 | 7.50 |

| 125 | 1/1/4" x 1/1/4" | 100 | 26.4 | 6.00 | 0.65 | 0.85 | 0.28 | 210 | 90 | 149 | 143 | 66 | 50 | 155 | 111 | 100 | 79 | 18 | 30 | 6 | 38 | 8.50 |

| 150 | 1/1/2" x 1/1/2" | 125 | 33.0 | 7.50 | 0.75 | 0.95 | 0.35 | 225 | 21 | 149 | 151 | 73 | 50 | 155 | 111 | 100 | 79 | 12 | 3 | 20.5 | 38 | 11.90 |

| 200 | 2" x 2" | 150 | 39.6 | 9.00 | 0.90 | 1.15 | 0.45 | 251 | 103 | 167 | 162 | 85 | 70 | 190 | 131 | 112 | 87 | 24 | 30 | 8 | 40 | 20.50 |

| 200 | 200 | 52.8 | 12.00 | 1.00 | 1.25 | 0.60 | 281 | 25 | 167 | 179 | 97 | 70 | 190 | 131 | 112 | 87 | 14 | 5 | 27 | 40 | 24.00 | |

| 250 | 2/1/2" x 2/1/2" | 250 | 65.0 | 15.00 | 1.20 | 1.40 | 0.65 | 299 | 122 | 197 | 206 | 93 | 85 | 200 | 161 | 132 | 102 | 28 | 40 | 8 | 50 | 35.00 |

| 250 | 300 | 80.0 | 18.00 | 1.40 | 1.65 | 0.77 | 319 | 30 | 197 | 218 | 101 | 85 | 200 | 161 | 132 | 102 | 16 | 5 | 32 | 50 | 40.00 | |

Special Note

For calculating the power requirement at duty point, multiply the duty point pressure with unit horse power & add no load viscous power of appropriate viscosity. Provide safety margin before fixing the ratting of the pri-mover. For high viscosity further marging may be kept or the manufacturer may be consulted. All sizes of JRG-SS pumps are designed to run at 1400 RPM up to viscosity of 500 CST, for small size pump up to 1" can be safely run at 1440 RPM even at higher viscosity up to 1000 CST with additional horse power. For sizes above 1" reduce the speed to 960 RPM for viscosity up to 1000 CST. For higher viscous liquid consult the manufacturer to avoid cavitation & overloading problem.

Application

This compact and efficient S.S. pump find various application for handling viscous food products like 1. Ghee 2. Butter 3. Fruit pulp 4. vegetable souse, kanji etc. They are also used on pharmaceutical industries for handling 1. sugar solution, 2. glycerin, 3. glycol etc. In chemical industries corrosive viscous chemicals can easy be handled with this pump most effectively.