JRMS/JRM

JRMS/JRM

This Series Contains foot mounted Special purpose pumps having flange mounting class 150# ASME / ANSI B16.5 at inlet & outlet ports. Material Of Construction. Pump Body : SS-316 (JRMS) / Graded CI Casting (JRM), Gears : SS-316 Double Helical -H Nitrided (JRMS) / SS-316 Single Helical - H. Nitrided (JRM). Shaft : SS - 316 -H. Nitrided & Ground. Bush : Teflon coated imported 'DU'Bushes (JRMS) / Wear Plaste cum brush bronze (JRM), Sealing : Teflon base 'Z' pack. Size : 1/2 " to 6" BSP. Range : 8.3 to 2080 LPM. Liquid : Liquids used in boilers & burners, Crude oil, Tar etc. JRMS Series contains in built pressure Relief valve. The pumps are used to handle corrosive, Thinner or thicker liquids having lesser lubricating value. The Maximum working pressure is 10kg/cm2.

Shivam Enterprise offer gear pump Model “JRMS”– heavy duty foot mounting type positive displacement rotary gear pump. Model “JRMS" is all stainless steel (SS-316) with flange (class 150# ASME/ANSI B16.5)

PUMP FEATURES

- The four piece construction in the pump makes it easy to clean & maintain and are designed to handle thinner or thicker or even corrosive liquid having lesser or no lubricating value.

- The pump is provided with double helical nitrated Gear to give longer life and also it helps to prevent axial and side thrust by increasing life and performance of the pump.

- The rotor of the pump runs on Teflon coated dry running DU Bush bearing supported on a bronze wearing plate, placed inside the pump casing and for heavier viscous liquid application, graphite/bronze wearing plate cum bushes are provided.

- The stuffing box is fitted with Gland Packing, with the provision to fit mechanical shaft seal.

- The pump is provided with add-on type pressure relief valve.

The pump can be operated up to maximum pressure of 10 Kg/cm2, flow capacity from 15 LPM to 500 LPM and are suitable for maximum temperature up to 2000 and maximum viscosity up to 1 SSU.

The pump with jacketing construction is provided to felicitate heating of the pump by steam or thermic fluid etc.

APPLICATION

- High pressure coolant transfer application for machine tools.

- Handling thinner liquid at moderate measuring.

- Light fuel pressurizing application for loader and burners.

- Heavy viscous liquid transfer application like Molasses, Magma, Tar, Soap Solution, Paints, Varnish, Sugar Juice, Vegetable Oil, Printing Ink, Paper Pulp, Spent Wash.

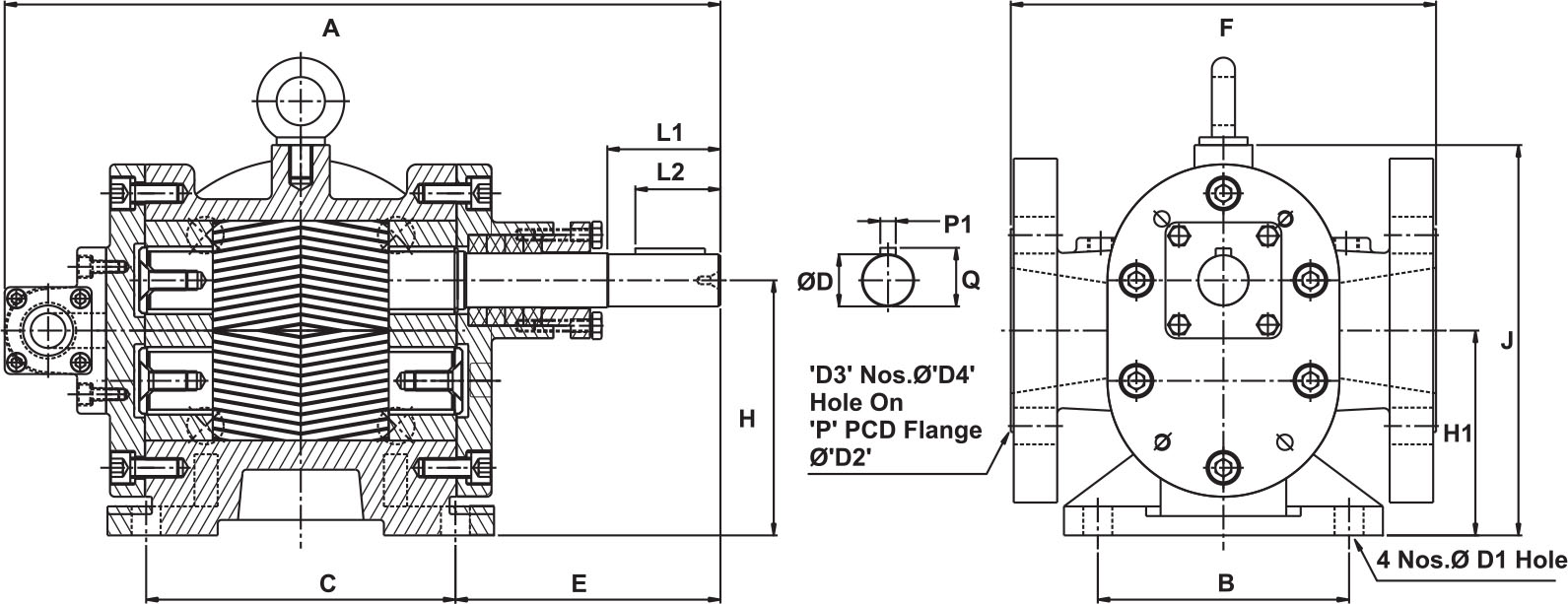

Dimensional Drawing

| Material of construction | ||

|---|---|---|

| Part | Material | |

| Pump Body | CF8M [SS-316] | |

| Front Cover | CF8M [SS-316] | |

| Back Cover | CF8M [SS-316] | |

| Gland Cover | CF8M [SS-316] | |

| Rotor & Stator Shaft | AISI [SS-316] | |

| Gear | AISI [SS-316] | |

| Bushes | Teflon Coated DU | |

| Wear Plate | Bronze | |

| R.V. Housing | AISI [SS-316] | |

| R.V. Piston | AISI [SS-316] | |

| R.V. Spring | Mild Steel | |

| R.V. AD. Screw | Mild Steel | |

| Кеу | AISI [SS-316] | |

| Sealing | Gland Packing | |

Model & Dimensional Drawing Details

| Pump Model JRMS | Capacity at 1440 RPM | Ele Motor (in H.P.) | Dimensions | Weight of pump (in kg.) |

||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LPM | US GPM | M3/hr | Overall | Mounting | Flange | Shaft | ||||||||||||||||||

| A | F | J | B | C | E | H | H1 | D1 | D2 | D3 | D4 | P | D | L | L1 | P1 | Q | |||||||

| 1/2" 50 |

S M |

15 20 |

3.9 5.2 |

0.9 1.2 |

0.50 0.75 |

220 | 150 | 120 | 80 | 100 | 76 | 80 | 69 | 09 | 89 | 4 | 16 | 60 | 11.5 | 26 | 26 | 4 | 13.8 | 8.5 |

| 1" 100 |

S M |

30 35 |

7.9 9.2 |

1.8 2.1 |

1.00 1.50 |

257 | 160 | 136 | 90 | 110 | 90.5 | 90 | 74 | 10 | 108 | 4 | 16 | 79 | 15 | 38 | 29 | 5 | 17.3 | 11.5 |

| 1/1/2" 150 |

S M |

60 75 |

15.8 19.8 |

3.6 4.5 |

2.00 3.00 |

300 | 180 | 157 | 105 | 130 | 104 | 100 | 80 | 10 | 127 | 4 | 16 | 98.4 | 21 | 45 | 34 | 6 | 23.8 | 12 |

| 2" 200 |

S M |

100 125 |

26.4 33.0 |

6.0 7.5 |

3.00 5.00 |

333 | 200 | 172 | 110 | 150 | 118 | 112 | 90 | 12 | 152 | 4 | 19 | 121 | 24 | 55 | 40 | 8 | 27.3 | 22 |

| 2/1/2" 250 |

S M |

150 200 |

39.6 52.8 |

9.0 12.0 |

5.00 7.50 |

370.7 | 220 | 202 | 130 | 160 | 137.5 | 132 | 106 | 15 | 178 | 4 | 19 | 139.7 | 27 | 58 | 44 | 8 | 30.3 | 28 |

| 3" 300 |

S M |

250 330 |

66.0 87.1 |

15.0 19.8 |

7.50 10.00 |

455 | 235 | 240 | 160 | 220 | 160 | 160 | 130 | 19 | 190 | 4 | 19 | 152 | 32 | 75 | 55 | 10 | 37 | 40 |

| 4" 400 |

S M |

415 500 |

109.6 132.0 |

24.9 30.0 |

10.00 15.00 |

530 | 275 | 270 | 180 | 270 | 170 | 180 | 145 | 19 | 229 | 8 | 19 | 190 | 36 | 85 | 65 | 10 | 41 | 69 |