JRN/JRB

JRN/JRB

This series contains genral purpose foot mounted pumps with flange mounting class 150# ASME / ANSI B16.5 at inlet & outlet ports.

Material oF Construction.

| Pump Body | Graded CI Casting. |

|---|---|

| Gears | Alloy Steel - Double Helical -H. |

| Nitride. Shaft | Alloy Steel - Case Hardened & ground |

| Bearings & Bushes | Needle Roller bearing (JRN) / Bronze Bushes (JRB). |

| Sealing | Oil Seal / Teflon base 'Z'pack. Size : ½"to 6" (8 different sizes). |

| Range | 8.3 to 2080 LPM. |

| Liquid | Crude oil, dirty oil, kerosene, LDO, HSD, Wood Pulp, Furnace oil etc. |

| Viscosity up to 1,00,000 SSU. temperature up to 200 °C. | |

| In Built Pressure Relief Valve is provided to achieve maximum working pressure 10kg/cm2. | |

Shivam Enterprise offer gear pump Model JRN/JRB heavy duty foot mounting type positive displacement rotary twin gear pump with flange (class 150# ASME/ANSI B16.5).

The Pump consists of a double helical refined gear along with a hardened grind finished shaft. The double helical gear prevents axial load & side thrust which increases the life and the performance of the pump.

The pump can be operated up to maximum pressure of 10 Kg/cm2, flow capacity from 10 LPM to 2080 LPM and are suitable for maximum temperature up to 200°C & maximum viscosity up to 1,00,000 SSU.

MODEL SELECTION:

Model JRN/JRB: for clean viscous liquid having sufficient lubricating values such as Vegetable Oil, Animal Oil, Fish Oil, Clean Tube Oil, Gear Oil, Hydraulic Oil, Gycerine, Automotive & Diesel Engine Oil etc. For intermitted duty, the bush bearing type of pump (JRB) is used and for continuous duty, needle roller bearing type of pump (JRN) is selected.

Model JRN: for liquid having low viscosity, low lubricating values, impure/dirty Crude Oil, dirty Lube Oil, HSD Kerosene, Sugar Solutions, LDO Paints, Wood Pulp, Varnish, Turpentine, the pump with independently lubricated bearing is selected.

Model JRB: the pump with the jacketing construction for liquid which tends to solidify at room temperature such as Bituman/Asphalt/Tar, Furnance Oil, Starch, Molasses, Naptha, Soap Solution, Wax etc. The jacketing construction in the pump facilitates heating of the pump by steam or thermic fluid.

FEATURES

- Heavy duty gear pump design for continuous application.

- Herringbone rotor design eliminate side thrust

- Modified tooth profile enhance tooth life

- Floating gear design ensures uniform load distribution.

- Optionally steam jacket available

- Double helical gear design prevent axial load.

- Low leakage path by design improve volumetric efficiency

- Shorter bearing span reduces bending effect

APPLICATION

- Power Plant

- Steel Plant

- Cement Plant

- Bitumen Plant

- Petroleum Industries

- Refineries

- Pumping Station

- All kind of liquid loading and unloading

| Material of construction | ||

|---|---|---|

| Part | Material For JRN/JRB | Material for JRB |

| Pump Body | CI/CS | CI/CS |

| Front Cover | CI/CS | CI/CS |

| Back Cover | CI/CS | CI/CS |

| Gland Cover | CI/CS | CI/CS |

| Rotor & Stator Shaft | EN-19 | EN-19 |

| Gear | EN-24 / 353 | EN-24 / 353 |

| Bush/Needle Bearing | INASIKO (Japan) | Non-Ferrous |

| Wear Plate | Bronze | Bronze |

| Lifting Hook | Mild Steel | Mild Steel |

| R.V. Housing | Mild Steel | Mild Steel |

| R.V. Piston | EN-8 | EN-8 |

| R.V. Spring | Mild Steel | Mild Steel |

| R.V. AD. Screw | EN-8 | EN-8 |

| Sealing | Neoprene Oil Seal | Gland Packaing |

| Кеу | EN-8 | EN-8 |

| Dowel Pin | EN-31 | EN-31 |

| Hex - Bolt | EN-8 | EN-8 |

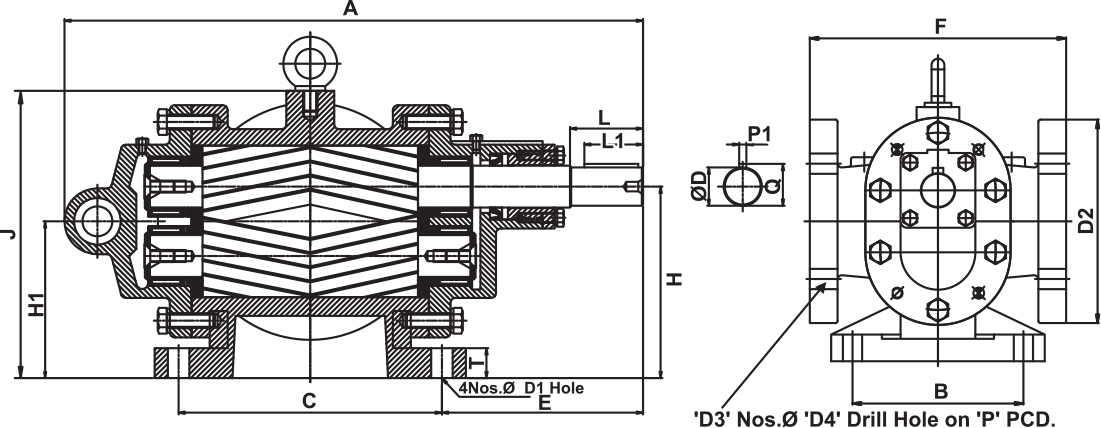

Model & Power Chart

| Size & Model JRN/JRB | Capacity at 1440 RPM | Ele Motor (in H.P.) | Dimensions | Wt. of pump (in kg.) |

|||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LPM | US GPM | M3/hr | Overall | Mounting | Flange | Shaft | |||||||||||||||||||

| A | F | J | B | C | E | H | H1 | T | D1 | D2 | D3 | D4 | P | D | L | L1 | P1 | Q | |||||||

| 1/2" 50 |

S M L |

10 15 25 |

2.6 3.9 6.6 |

0.6 0.9 1.5 |

0.50 0.75 1.00 |

242 | 150 | 120 | 80 | 100 | 91 | 80 | 69 | 13 | 10 | 89 | 4 | 16 | 60 | 11.5 | 30 | 22 | 4 | 13 | 7 |

| 1" 100 |

S M L |

30 50 60 |

7.9 13.2 15.18 |

1.8 3.0 3.6 |

0.75 1.00 2.00 |

277 | 160 | 136 | 90 | 110 | 102 | 90 | 74 | 15 | 10 | 108 | 4 | 16 | 79 | 15 | 30 | 25 | 5 | 17 | 13 |

| 1/1/2" 150 |

S M L |

80 100 125 |

21.1 26.4 33.0 |

4.8 6.0 7.5 |

2.00 3.00 5.00 |

321 | 180 | 157 | 105 | 130 | 119 | 100 | 80 | 16 | 127 | 89 | 4 | 16 | 98 | 21 | 40 | 29 | 6 | 23.5 | 18 |

| 2" 200 |

S M L |

150 165 200 |

39.6 43.5 52.8 |

9.0 9.9 12.0 |

3.00 5.00 7.50 |

365 | 200 | 172 | 110 | 150 | 134 | 112 | 90 | 15 | 12 | 152 | 4 | 19 | 121 | 24 | 50 | 39 | 8 | 27 | 23 |

| 2/1/2" 250 |

S M L |

250 300 330 |

66.0 79.2 87.1 |

15.0 18.0 19.8 |

5.00 7.50 10.00 |

420 | 220 | 202 | 130 | 160 | 163 | 132 | 106 | 24 | 15 | 178 | 4 | 19 | 140 | 27 | 55 | 40 | 8 | 30 | 38 |

| 3" 300 |

S M L |

415 450 500 |

109.6 118.8 132.0 |

24.9 27.0 30.0 |

10.00 12.50 15.00 |

483 | 240 | 238 | 160 | 220 | 168 | 160 | 131 | 25 | 18 | 190 | 4 | 19 | 152 | 32 | 55 | 49 | 10 | 35 | 57 |

| 4" 400 |

S M L |

600 665 830 |

158.5 175.6 219.2 |

36.0 39.9 49.8 |

15.00 20.00 25.00 |

560 | 280 | 272 | 180 | 270 | 189 | 180 | 145 | 24 | 18 | 229 | 8 | 19 | 190 | 37 | 65 | 54 | 10 | 40 | 87 |

| 5" 500 |

S M L |

1000 1250 1500 |

264.1 330.2 396.2 |

60.0 75.0 90.0 |

20.00 30.00 40.00 |

615 | 300 | 296 | 200 | 280 | 216 | 200 | 160 | 25 | 20 | 254 | 8 | 22 | 216 | 47 | 83 | 58 | 14 | 51 | 151 |

| 6" 600 |

S M L |

1650 1825 2080 |

435.8 482.1 549.4 |

99.0 109.5 124.8 |

30.00 50.00 60.00 |

697 | 340 | 340 | 220 | 350 | 216 | 225 | 178 | 25 | 20 | 280 | 8 | 22 | 241 | 52 | 93 | 82 | 16 | 56 | 167 |