The INTERNAL GEAR pumps are based on the proven rotary trochoidal design - gerotor principle. The pumps are designed to meet

specific demands of OEM's. The reliable performance of the JIG series makes them anideal choice for various industrial applications.

SPECIAL EXECUTIONS

- Specially coated internals for pumping of non-lubricating liquids.

- Engineering plastics rotor set for chemicals & low viscosity fluids

- Specially designed pumps for vacuum duty applications

- Uni-directional

ADVANTAGES OF INTERNAL GEAR PUMPS

- Single shaft-well supported at both ends

- High suction lift and low noise level as well as vibrations

- High volumetric and overall efficiency

- Continuous, pulsation free flow due to axial entry in pumping element

- Compact and light-weight design

- Ease of assembling and dismantling without disturbing the pipeline.

- Choice of oil seal / Mechanical seal/gland pack.

- Parts / Pumps interchangeable with well known brands.

TYPICAL APPLICATION

- Transfer from tank to tank

- Emptying of barrels

- Lubricating and cooling of bearings, gears, Mechanical seals and machine tools

- Fuel oil booster

LIQUIDS HANDLED

- Fuel oil

- Lube Oil

- Neutral liquids with lubricating properties

APPLICATIONS

- Filter pumping

- Pressure and transfer pump

- Pump for PHF units

- Pump for force feed lubrication

- Booster pump for diesel locomotive

- Oil burner

- Hydraulic drive and pressure pump - for gas oil, medium. Heavy and very heavy oil

- Transformers

- Boilers

- Vegetable oil processing

- Furnaces

- Suitable for LDO, FO, HSD & LSHS

Performance table (JIG Series)

| Model |

Inlet Outlet Sizes |

Capacity in LPH |

Speed RPM |

Recommended Motor HP |

|

|

|

|

5 kg/Cm2 |

15 kg/Cm2 |

30 kg/Cm2 |

| JIG-150 |

1/2" x 1/2" BSP |

150 |

1440 |

0.25 HP |

0.75 HP |

1.5 HP |

| JIG-300 |

300 |

0.25 HP |

0.75 HP |

1.5 HP |

| JIG-450 |

450 |

0.50 HP |

1 HP |

2 HP |

| JIG-600 |

600 |

0.50 HP |

1 HP |

2 HP |

| JIG 1000 |

3/4" x 3/4" BSP |

1000 |

0.75 HP |

2 HP |

3 HP |

| JIG 1500 |

1500 |

0.75 HP |

2 HP |

3 HP |

| JIG 2000 |

2000 |

1 HP |

3 HP |

5 HP |

| JIG 2500 |

2500 |

1 HP |

3 HP |

5 HP |

MATERIAL OF CONSTURUCTION

| Pump Body |

C.I. GR 25 |

| Shafted Rotor |

EN-31 H & G |

| Eccentric Cover |

C.I. GR 25 |

| Idler Gear |

EN-31 H & G |

| Mechinical Seal Housing |

MS |

| Wear Plate |

PH-BRONZE |

- Normal flow at 1440 or 2880 RPM with oil viscosity 32 CST at 37.5°C at normal working temperature and 10 kg/cm pressure

- igher or lower pressure on request.

- Direction of rotation as viewed from shaft end.

- L-anti clockwise

- R-clockwise

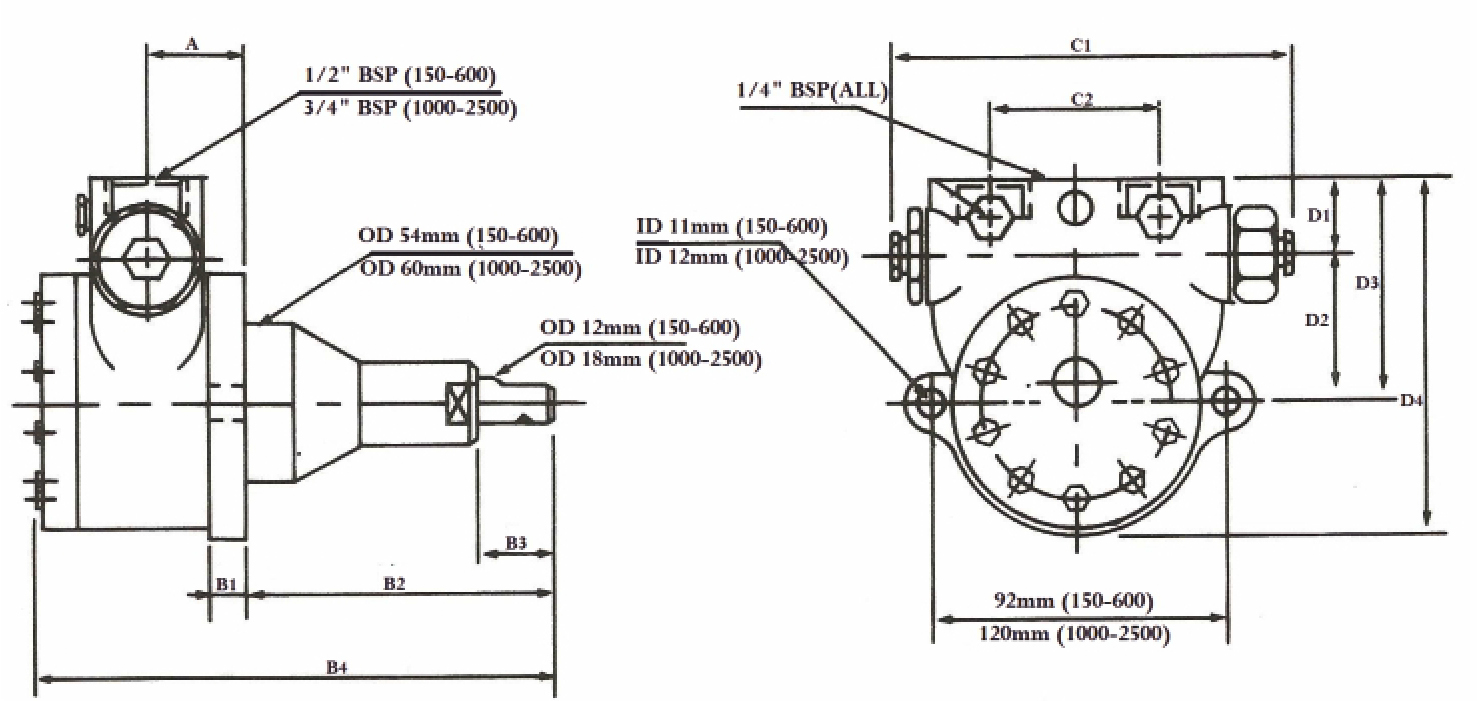

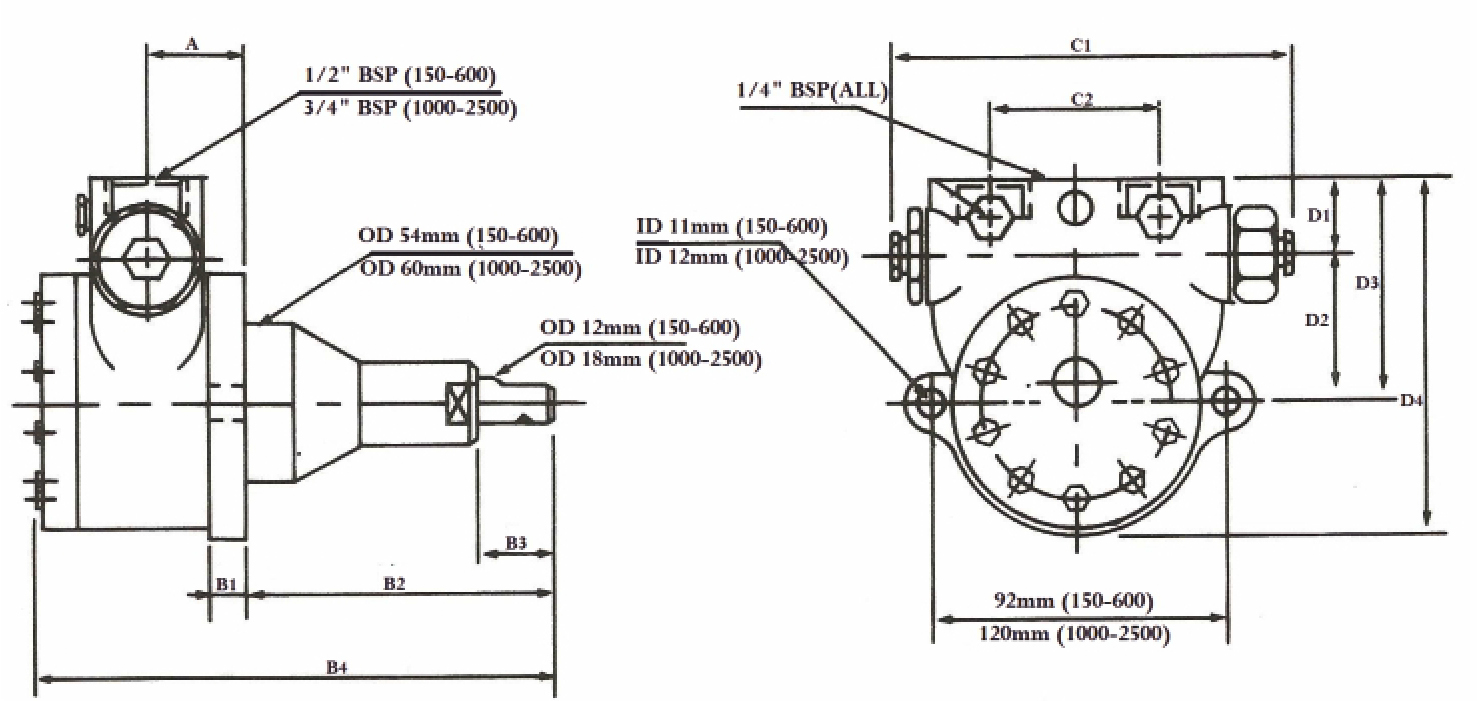

Dimensional Drawing Details

| Model |

Flow in L/H |

A |

B1 |

B2 |

B3 |

B4 |

C1 |

C2 |

D1 |

D2 |

D3 |

D4 |

|

1400 RPM |

2880 RPM |

|

|

|

|

|

|

|

|

|

|

|

| JIG |

150-600 |

300-900 |

30 |

13 |

77 |

25 |

146 |

139 |

44 |

27 |

48 |

75 |

115 |

| JIG |

1000-2500 |

- |

39 |

15 |

124 |

29 |

211 |

162 |

67 |

35 |

55 |

90 |

140 |

Download PDF

Download PDF